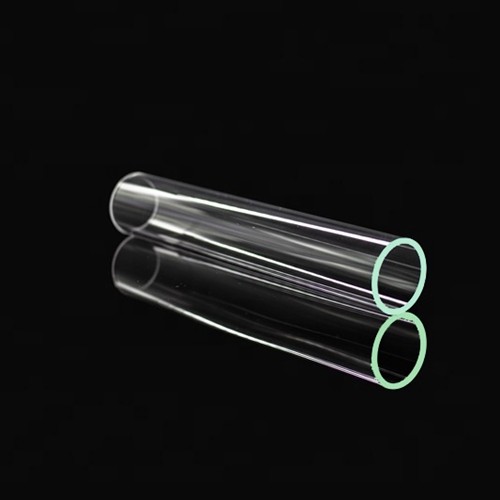

Soda Lime Glass, the Backbone of Everyday Glassware

The Global Soda Lime Glass Market is projected to grow from USD 95.54 Billion in 2023 to over USD 139.80 Billion by 2029 at a CAGR of 6.69%.

The polymer fillers market is experiencing significant growth, driven by the rising demand for cost-effective, high-performance materials across industries such as automotive, construction, packaging, and electronics. Polymer fillers play a crucial role in improving the properties of polymers, including mechanical strength, durability, thermal stability, and cost-efficiency, making them indispensable for modern manufacturing. As industries seek lightweight, durable, and sustainable solutions, the demand for polymer fillers such as calcium carbonate, silica, clay, and carbon black is rising. Innovations in filler technology are addressing the need for customized solutions, offering tailored properties to meet specific application requirements. Additionally, the shift toward eco-friendly materials and bio-based fillers is shaping the future of the market, aligning with global sustainability goals and reducing the environmental impact of polymer-based products.

A prominent trend in the polymer fillers market is the growing adoption of natural and mineral-based fillers, driven by their cost-effectiveness, availability, and environmental benefits. Fillers such as calcium carbonate and talc are widely used in industries like packaging and automotive, where they enhance stiffness, improve dimensional stability, and reduce overall production costs. In parallel, the increasing use of silica and glass fillers in electronics and construction applications is boosting market demand, given their ability to improve thermal and mechanical performance. Technological advancements have further led to the development of functional fillers that provide enhanced properties, including flame retardancy, conductivity, and lightweight characteristics, meeting the evolving needs of high-performance applications.

The expanding polymer fillers market is transforming manufacturing by reducing costs and enhancing product quality across multiple sectors. In the automotive industry, the use of lightweight polymer fillers contributes to vehicle weight reduction, improved fuel efficiency, and reduced emissions, aligning with global environmental standards. In packaging, fillers enable manufacturers to produce cost-efficient, durable, and recyclable materials, addressing the increasing consumer demand for sustainable solutions. However, challenges such as price volatility of raw materials, environmental concerns regarding synthetic fillers, and limited performance in specific applications persist. Despite these hurdles, polymer fillers provide numerous benefits, such as improved mechanical strength, thermal resistance, and reduced material usage, making them a critical component in industrial manufacturing.

Among the key segments, mineral fillers such as calcium carbonate and talc dominate the polymer fillers market due to their versatility, cost efficiency, and ability to enhance material properties. Calcium carbonate, in particular, is widely used across packaging and construction applications for its low cost and ability to improve stiffness and durability. Additionally, carbon black fillers are critical in tire manufacturing and electrical applications, providing reinforcement and conductivity. Opportunities lie in the development of bio-based and functional fillers, which are gaining traction for their sustainable and performance-enhancing properties. Drivers such as growing demand for lightweight materials, increased focus on cost reduction, and advancements in nanofillers are opening new avenues for market growth, enabling industries to adopt innovative filler technologies.

The future of the polymer fillers market looks highly promising, driven by technological innovation, growing sustainability efforts, and increasing demand for high-performance materials. Emerging trends such as the use of nanofillers and bio-based fillers are expected to revolutionize the market, offering enhanced mechanical, thermal, and environmental benefits. Industries like automotive and electronics will continue to be major growth drivers, leveraging lightweight and functional fillers to meet performance and regulatory requirements. The push for circular economies and eco-friendly solutions will encourage manufacturers to adopt sustainable filler technologies, reducing carbon footprints and resource dependency. To stay competitive, businesses must focus on R&D, develop application-specific solutions, and explore sustainable alternatives that address industry demands for efficiency, performance, and environmental responsibility.

See how you can up your career status

The Global Soda Lime Glass Market is projected to grow from USD 95.54 Billion in 2023 to over USD 139.80 Billion by 2029 at a CAGR of 6.69%.

The global Carbon Steel market, valued at more than USD 1035.02 Billion in 2024, is expected to reach USD 1306.14 Billion by 2030, with a 4.04% CAGR.

The global steel rebar market is projected to reach USD 333.61 billion by 2030, growing at a 4.78% CAGR from 2025 to 2030.

We are friendly and approachable, give us a call.

We are friendly and approachable, give us a call.