The Core Metal Fueling Global Growth

The global Carbon Steel market, valued at more than USD 1035.02 Billion in 2024, is expected to reach USD 1306.14 Billion by 2030, with a 4.04% CAGR.

Steel rebar, short for reinforcement bar, has quietly become one of the most vital components in the world’s construction landscape. It forms the skeletal strength behind towering skyscrapers, sturdy bridges, long highways, and complex infrastructure systems. As nations expand and urban centers evolve, the importance of steel rebar grows steadily. Its usage is not limited to large-scale development alone; it finds a place in residential and commercial projects alike, ensuring the durability and safety of structures. What makes steel rebar especially significant today is the world’s renewed focus on resilient and sustainable construction practices. The demand for earthquake-resistant buildings, flood-proof infrastructure, and energy-efficient urban layouts is increasing, and at the core of all these lies strong reinforcement — which only steel rebar can provide at scale. As cities modernize and the global population migrates toward urban hubs, steel rebar is proving to be more than just a supporting player; it is the foundation of the future.

The steel rebar market has seen a surge in momentum, shaped largely by booming construction activities across both developed and developing regions. Infrastructure has taken center stage in national development agendas, especially in countries undergoing rapid industrial growth. From metros and airports to tunnels and flyovers, all major civil engineering projects rely heavily on reinforced concrete, and thus on steel rebar. Governments are heavily investing in infrastructure to stimulate economic growth and provide employment, which in turn is directly feeding into the demand for steel reinforcement materials. For example, several countries in Asia have committed to multi-year infrastructure development programs, channeling funds into urban connectivity, housing, and public utilities. In parallel, private real estate investment is growing in metropolitan regions around the world, fueled by population shifts and demand for modern housing. This confluence of public infrastructure spending and private sector expansion is keeping the steel rebar market highly active. The need for rebar is also strengthened by regulatory updates requiring stronger structural frameworks to withstand environmental pressures such as earthquakes and extreme weather events. Technological upgrades in steel processing and recycling have further added to the efficiency and environmental appeal of using steel rebar over other materials.

As demand accelerates, the impact on the construction and materials industry is profound. Construction companies are adapting their strategies to secure stable and cost-effective steel rebar supply, often entering long-term contracts to manage fluctuations in price and availability. Manufacturers, on the other hand, are scaling up operations, improving production capabilities, and introducing customized variants of rebar to meet evolving market needs. This includes rebar with added corrosion resistance for marine structures or higher tensile strength for high-rise buildings. Retailers and distributors are expanding their inventories and logistics networks to ensure timely delivery across construction sites globally. The rising demand is not without its challenges. Price volatility in raw materials such as iron ore, energy costs for production, and global supply chain disruptions can significantly affect the stability of the market. Moreover, environmental concerns associated with steel production have led to increasing pressure on manufacturers to adopt sustainable practices. However, this pressure has also catalyzed innovation. Many producers are now exploring electric arc furnaces, scrap-based production, and green energy sourcing to reduce carbon footprints. For consumers and construction firms, the benefits are numerous — from stronger, longer-lasting buildings to compliance with safety and environmental norms.

Among the various product types available in the market, deformed steel rebar stands out due to its superior performance characteristics. Unlike plain rebar, deformed rebar features ridges or patterns on its surface, which enhance its grip within concrete, making it ideal for use in structural applications where maximum bond strength is essential. This type of rebar has gained widespread acceptance in large infrastructure projects, residential complexes, and commercial developments. The popularity of deformed steel rebar is driven not only by its mechanical properties but also by evolving building standards that increasingly demand higher safety and strength metrics. Its application in earthquake-prone regions is particularly significant, as it offers additional structural stability under seismic stress. Opportunities for deformed rebar are growing as construction activity picks up pace in emerging economies and as reconstruction projects get underway in post-disaster areas. Manufacturers are continuously investing in the development of deformed rebar variants that are easier to work with on site, resist corrosion even in high-moisture environments, and maintain structural integrity over long periods. In addition, industry players are now looking at hybrid reinforcement systems, where deformed rebar is used in combination with composite materials to deliver even higher strength and resilience. These innovations are making deformed steel rebar not just a construction necessity but a strategic asset in infrastructure development.

Looking ahead, the future of the steel rebar market appears both dynamic and promising. With rising urban populations, climate-resilient construction, and energy-efficient buildings becoming global priorities, the role of steel rebar is likely to grow more prominent. One of the emerging trends includes the integration of smart construction technologies, such as 3D modeling and building information modeling, which enable precise planning and placement of rebar in complex structures. Such innovations reduce material wastage, lower costs, and improve overall build quality. Sustainability is also a key driving factor. Governments are setting stricter emissions targets, and the construction industry is under pressure to use greener materials. This is prompting rebar manufacturers to explore the use of recycled scrap metal, green hydrogen in steelmaking, and circular supply chains to make their products more eco-friendly. Additionally, automated machinery and robotics are being introduced at construction sites to handle rebar with greater precision and safety, thus improving labor efficiency and reducing errors. For stakeholders across the board — from policymakers and architects to engineers and investors — staying informed about these trends and preparing for a more sustainable, efficient future is crucial. Embracing innovation, fostering collaboration between industries, and committing to environmentally sound practices will ensure that steel rebar continues to support the structures that shape our world, both literally and metaphorically.

See how you can up your career status

The global Carbon Steel market, valued at more than USD 1035.02 Billion in 2024, is expected to reach USD 1306.14 Billion by 2030, with a 4.04% CAGR.

The Polymer Filler market is anticipated to cross USD 71 Billion by 2029, increasing from USD 55.70 Billion in 2023. The market is expected to grow with a 4.29% CAGR from 2024 to 2029.

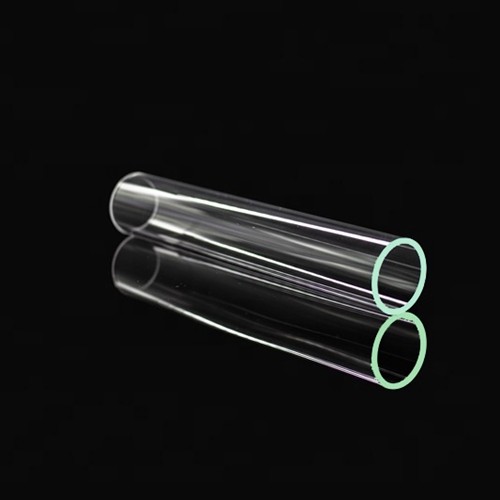

The Global Soda Lime Glass Market is projected to grow from USD 95.54 Billion in 2023 to over USD 139.80 Billion by 2029 at a CAGR of 6.69%.

We are friendly and approachable, give us a call.

We are friendly and approachable, give us a call.