Railing Revolution, A New Era of Design and Safety

The Global Railing market is anticipated to cross USD 72 Billion by 2029, increasing from USD 52.81 Billion in 2023. The market is expected to grow with a 5.53% CAGR from 2024 to 2029.

The construction industry is embracing innovation like never before, and one of the standout materials leading this transformation is construction fabric. Often lightweight yet incredibly strong, construction fabrics are now a go-to choice for builders and architects seeking durability, flexibility, and cost efficiency. From protective scaffolding wraps to tensile architectural membranes, these textiles are playing a crucial role in modern construction projects across the globe. The demand for sustainable and efficient building solutions is pushing the industry to rethink traditional materials, and construction fabrics are answering the call with versatility and eco-friendly benefits. As cities grow vertically and infrastructure demands become more complex, the market for construction fabrics is experiencing rapid growth, fueled by technological advancements and a shift towards greener building practices.

A significant trend shaping the construction fabric market is the increasing focus on sustainable building materials. With global climate goals and environmental regulations tightening, builders are seeking eco-friendly alternatives to traditional concrete, metal, and plastic components. Construction fabrics, often made from recyclable or low-emission materials such as polyethylene, PTFE, and ETFE, offer a lightweight, energy-efficient solution. These fabrics are not only easier to transport and install, but they also reduce the carbon footprint of construction projects. Moreover, the rise of smart textiles integrated with insulation or UV-protection features is further transforming how fabrics are used in construction. The increasing use of tensile structures in stadiums, airports, and commercial buildings is also propelling demand. As the industry leans into modular construction and prefab solutions, construction fabrics are poised to become a core component of efficient, modern building practices.

The growing use of construction fabric is significantly impacting how projects are designed, executed, and maintained. For developers and architects, these fabrics open up creative possibilities in building design, allowing for large-span roofs, domes, and canopies without the need for heavy support structures. This reduces material costs and construction time, creating both economic and logistical advantages. For consumers and occupants, construction fabrics enhance comfort by offering better natural lighting, insulation, and ventilation options. Retailers and manufacturers are also seeing benefits, as the need for specialized fabrics has created opportunities to innovate and diversify product offerings. However, challenges persist, including the durability of certain fabric types under extreme weather conditions and the high initial cost of premium-grade materials like PTFE-coated fiberglass. Additionally, while fabric structures are often easier to install, they can require highly specialized engineering to ensure safety and stability. Despite these issues, the advantages such as cost efficiency, reusability, and aesthetics are outweighing the drawbacks for most stakeholders, cementing construction fabrics as a game-changer in the industry.

Among the different types of construction fabrics, polymer-coated fabric is currently leading the market due to its excellent balance of durability, flexibility, and weather resistance. These fabrics, often coated with materials like PVC, PTFE, or silicone, are used in everything from temporary tents and scaffolding covers to permanent roofing and facades. The key drivers behind the dominance of this segment include increased investment in public infrastructure projects and the growing popularity of fabric-based pavilions and stadiums. Opportunities abound as these fabrics also offer fire resistance, UV protection, and are easier to clean and maintain than traditional materials. In regions prone to harsh weather, polymer-coated fabrics provide a durable shield while allowing natural light to permeate the structure. Moreover, the ability to customize colors, textures, and shapes gives architects and designers the freedom to create iconic landmarks. This flexibility makes polymer-coated fabrics particularly attractive in markets such as the Middle East, Asia-Pacific, and Europe, where ambitious architectural projects are on the rise. Innovations in nanotechnology and bio-based coatings are also expected to further enhance the performance and environmental appeal of these fabrics, setting the stage for the next wave of sustainable construction solutions.

Looking ahead, the future of the construction fabric market is promising and filled with innovation. As urbanization accelerates and the global construction boom continues, demand for flexible, sustainable, and aesthetic building materials will remain high. Emerging trends like 3D-printed fabrics, self-cleaning textiles, and smart materials embedded with sensors are already making headlines and are expected to hit the market in the coming years. These innovations could enable fabrics to respond to environmental changes, improve energy efficiency, and even enhance building safety. Growth opportunities will be especially strong in developing economies where infrastructure development is a priority, and governments are investing heavily in smart cities and green building initiatives. To adapt, manufacturers must focus on research and development, partnerships with architects and engineers, and education on the long-term value of fabric-based structures. End users, from contractors to real estate developers, should consider integrating construction fabrics early in the design process to maximize their benefits. Ultimately, construction fabric is more than a building material—it’s a futuristic design solution shaping the skylines of tomorrow.

See how you can up your career status

The Global Railing market is anticipated to cross USD 72 Billion by 2029, increasing from USD 52.81 Billion in 2023. The market is expected to grow with a 5.53% CAGR from 2024 to 2029.

The market is anticipated to cross USD 20 Billion by 2029, increasing from USD 14.36 Billion in 2023. The market is expected to grow with a 7.18% CAGR from 2024 to 2029.

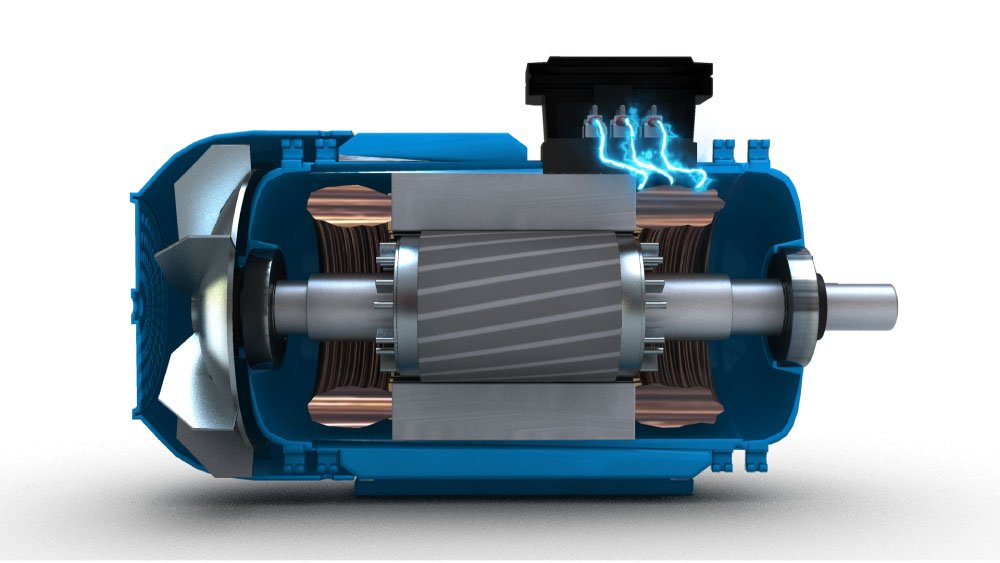

Global Electric Motor Market Outlook, 2029†published by Bonafide Research, the market is anticipated to cross USD 220 Billion by 2029, increasing from USD 141.37 Billion in 2023.

The Steel Wire market is anticipated to cross USD 97 Billion by 2029, increasing from USD 69.21 Billion in 2023. The market is expected to grow with a 5.84% CAGR from 2024 to 2029.

We are friendly and approachable, give us a call.

We are friendly and approachable, give us a call.